One Architecture | Two Stacks | Maximum Performance

CUBE ELECTROLYSIS PEM-STACKS

The production of green hydrogen on an industrial scale requires high-performance solutions. Our stacks combine efficiency and cost-effectiveness – without compromising on performance and H2 yield.

Our PEM Stacks

We didn’t reinvent PEM electrolysis – but we redefined its potential.

Proven components, optimized architecture, maximum performance – for a new class of compact high-performance stacks.

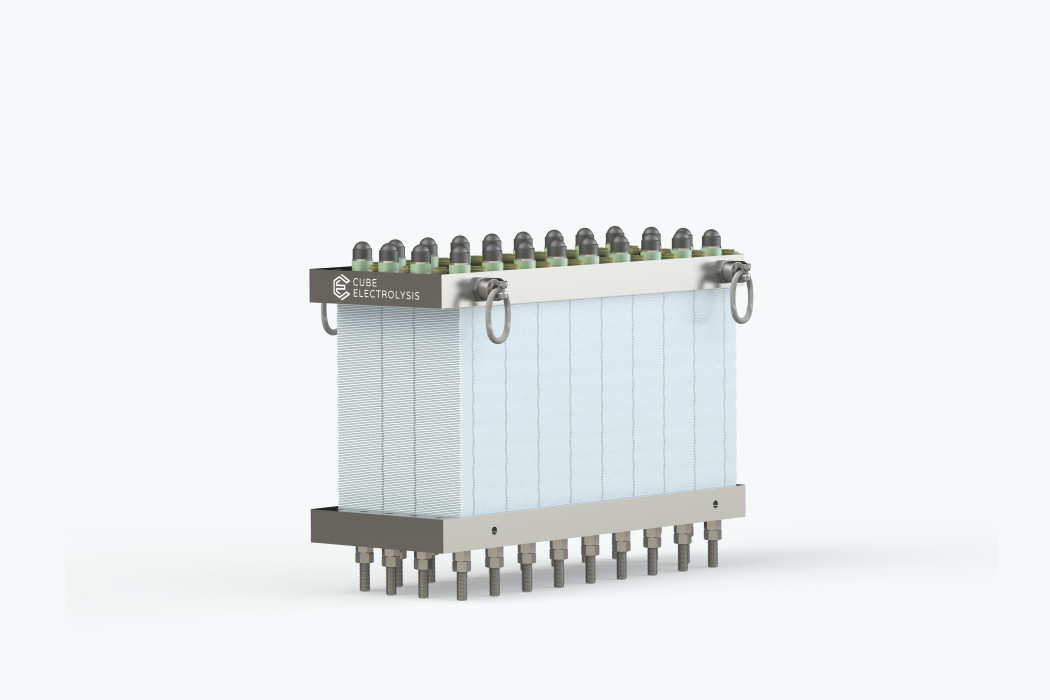

Cube - S1

0,5 MW

Nominal power

-

Hydrogen production:

10,3 kgH2/h

-

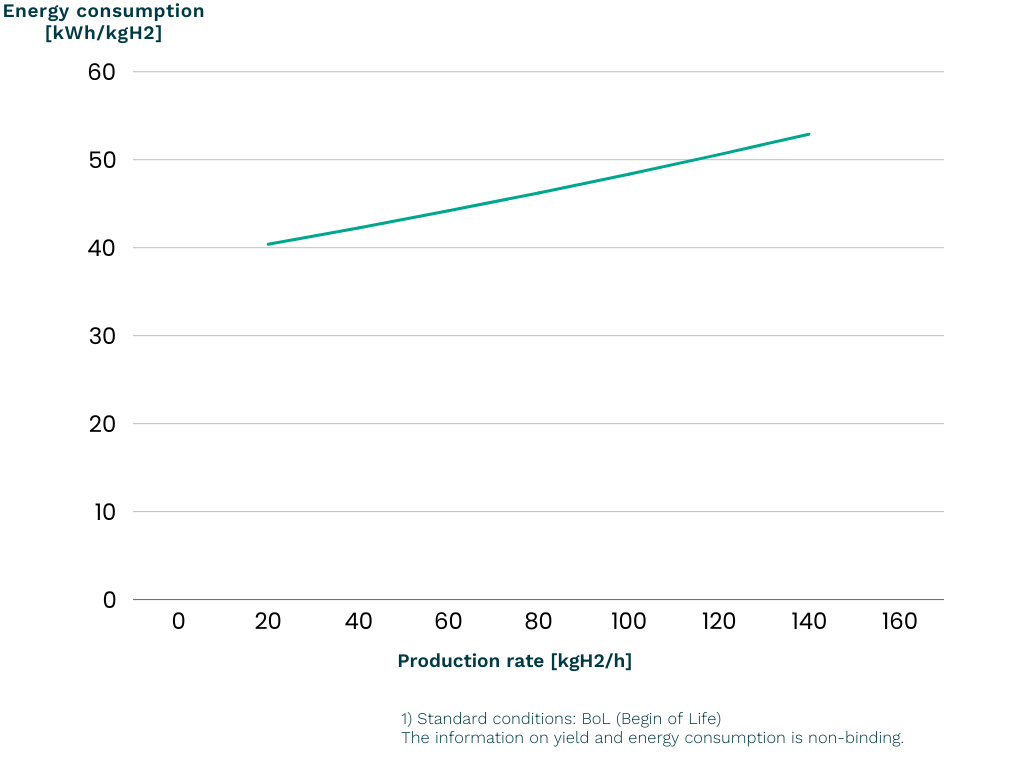

Energy consumption:

48.6 kWh/kgH2

-

Efficiency:

81,1% (HHV) / 68,5% (LHV)

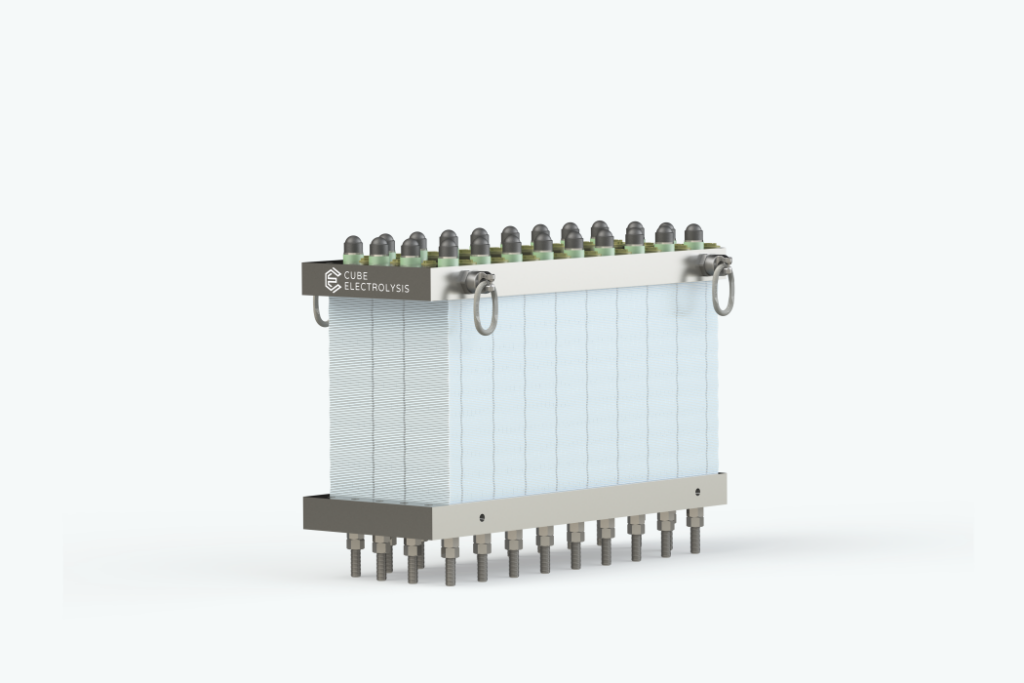

Cube - S6

5 MW

Nominal power

-

Hydrogen production:

103 kgH2/h

-

Energy consumption:

48,6 kWh/kgH2

-

Efficiency:

81,1% (HHV) / 68,5% (LHV)

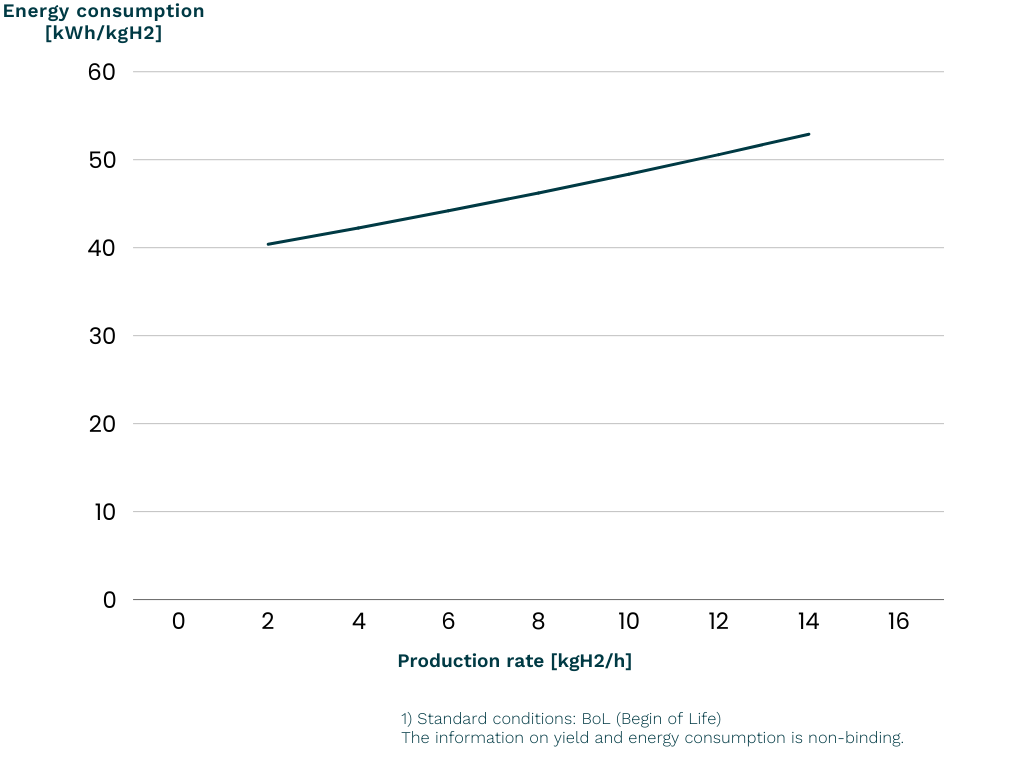

Our technology

Highest current densities and minimal cell voltages are the key to maximum performance and cost reduction in PEM electrolysis – our stack architecture goes beyond the technical limits of scalability and unlocks new potential for cost savings.

Cell architecture

Our cell architecture combines optimized active area dimensions with an innovative media distribution structure for maximum performance. We eliminate complex manufacturing processes and consistently rely on an RPS-controlled 2D layer design with standard-sized purchased components – the foundation for highly automated series production that meets the highest quality standards.

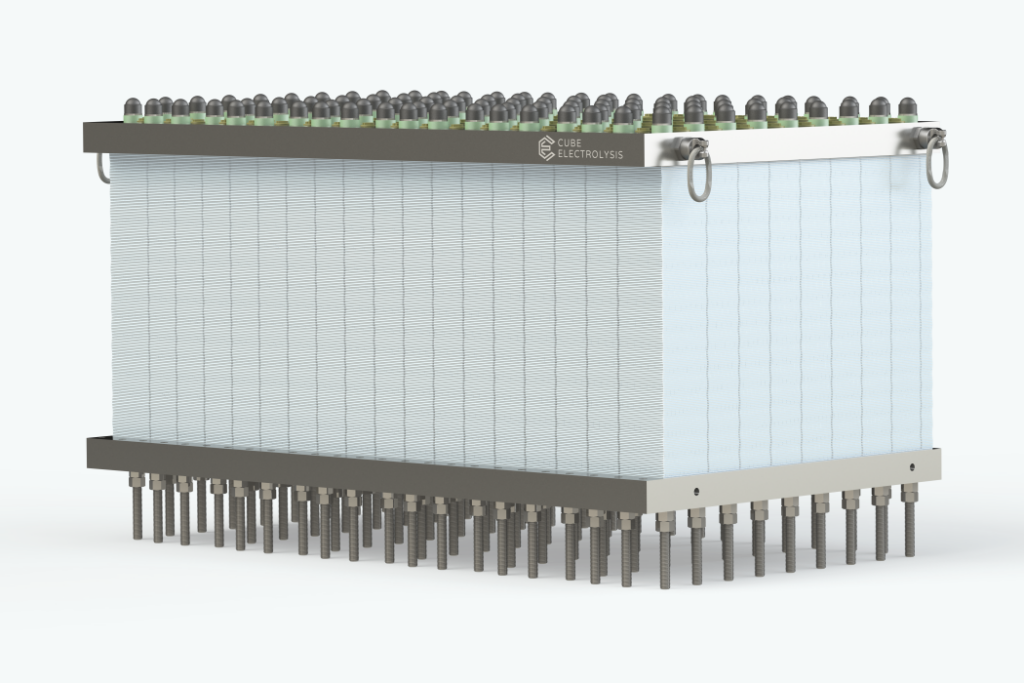

Cell platform

Our modular cell platform integrates optimized active area elements into a space-saving and cost-efficient multi-megawatt stack. This enables cross-product utilization of economies of scale from the mass production of our standardized active area components while simultaneously reducing manufacturing costs – further enhanced by the Balance of Plant advantages of large-format stacks.

Invest in the future – Together with Cube Electrolysis

As a test partner, you can experience the performance of our technology firsthand. Benefit from minimal risk and maximum potential.

Technical data

max. input power¹

0,73 MW

max. H2 production rate¹

332,7 kg/d

max. operating temperature

80°C

max. H2 delivery pressure

30 bar

dimensions

65 cm x 25 cm x 40 cm

max. input power¹

7,3 MW

max. H2 production rate¹

3.327,2 kg/d

max. operating temperature

80°C

max. H2 delivery pressure

30 bar

dimensions

65 cm x 122 cm x 60 cm

Our technology - your benefits

Reliable peak performance

Outstanding yield values combined with maximum reliability – ensuring smooth and continuous operation of your electrolyzers.

Global production capacity

Our cell architecture enables the rapid expansion of production capacities worldwide – flexible and precisely where you need them.

Cost-efficient production

Economical series production even at low volumes – ensuring maximum flexibility in the dynamic hydrogen electrolysis market.

Future-proof technology

Our cell architecture is already optimized for increasing current densities and enables continuous performance improvements – ensuring your competitive edge for the future.

Reliable partnerships

We rely on raw materials and components from leading international suppliers – for quality and security you can trust in the long term.

Sustainability in focus

Reduced material consumption and increased energy efficiency define our cell architecture – a solution that supports your sustainability goals while conserving resources.

Shaping the future of hydrogen production together

Have we sparked your interest?

Become our test partner or learn more about our technology.

Time table to market – From idea to series production

With Cube Electrolysis, we are setting new standards in PEM electrolysis. Our clearly defined development milestones document the progress of an innovative project that redefines efficiency, flexibility, and cost-effectiveness.

From the concept phase to series production, we are driving forward a technology that meets the demands of modern hydrogen production and paves the way for a sustainable energy future.

The starting point for a new era of PEM electrolysis: With the aim of developing large-format bipolar plates for multi-megawatt systems, we quickly recognized the limitations of mere surface scaling. Instead, we focused on a cell architecture that combines maximum current density, efficiency, and reliability.

Through targeted simulations and extensive laboratory testing, we laid the foundation for our innovative PEM stack architecture. At the core of our efforts was the development of a cell design that merges peak performance with industrial scalability.

A major milestone in development: The proof of concept confirmed the performance of our innovative cell architecture under real-world conditions. With an active area of 1,000 cm², the stack achieved market-ready values for current density and efficiency.

This success laid the foundation for the next development phase: designing for series production.

The first step toward series product: With a short stack based on selected series components, we recorded the performance parameters of our future series stack for the first time. By using production-ready conditions, we ensured that the results could be seamlessly transferred to the full stack.

This milestone marks a significant step toward market readiness.

Your entry into the future of hydrogen production: The full stack is built under near-series production conditions and prepared for deployment at a test partner site. This crucial phase gives you the opportunity to experience the performance and efficiency of our technology in real-world applications.

Seize the opportunity to be part of a groundbreaking project and help shape the hydrogen production of tomorrow.

Why Cube Electrolysis is your best choice

The future of hydrogen production requires technologies that are flexible, efficient, and sustainable. PEM electrolysis offers clear advantages that are crucial in a dynamic market environment. Cube Electrolysis takes the benefits of PEM electrolysis to the next level. Our PEM stacks provide you with a unique combination of efficiency and performance.

Optimal use of renewable energy

PEM systems offer maximum flexibility and adapt perfectly to fluctuating energy sources such as wind and solar power – enabling efficient and sustainable hydrogen production.

Maximum flexibility in site selection

PEM electrolysis operates without liquid hazardous substances and without external heat sources – providing maximum freedom in site selection.

Versatile applications

The advantages of PEM electrolysis allow for a broad spectrum of applications – from small decentralized solutions to large-scale industrial hydrogen production.

Highest hydrogen quality

PEM electrolysis produces hydrogen of the highest purity – an ideal foundation for versatile applications and direct industrial processing.

Invest in the future – Together with Cube Electrolysis

As a test partner, you can experience the performance of our technology firsthand. Benefit from minimal risk and maximum potential.

Technology and experience – The foundation of Cube Electrolysis

Finow Automotive Eberswalde – Experience in large-scale production meets innovation in sustainable hydrogen technology.

Precision, quality, and innovation – as an established supplier to the automotive industry, Finow Automotive brings state-of-the-art manufacturing technologies to the world of PEM electrolysis. With highly automated production processes and extensive expertise in laser cutting, hydroforming, and assembly manufacturing, we are setting new standards for hydrogen technologies.

Since 2021, we have been developing PEM electrolysis stacks to push the performance limits of hydrogen production. Our goal: a scalable, high-performance electrolysis technology that paves the way for a sustainable and efficient hydrogen economy.

With this ambition, we have created a new cell architecture that makes industrial hydrogen production more cost-effective and powerful.

With this ambition, we have created a new cell architecture that makes industrial hydrogen production more cost-effective and powerful.

Your partner for innovative PEM electrolysis solutions

Contact us to collaborate on the solutions of tomorrow.